The size was largely dictated by a bit of dead space in my office between my desk and a side table. I also wanted something lower than my desk for keyboard height and to deal with the issue that many synthesizer modules require you to look directly at their face to see and operate them.

I decided 24 inches was a good height for the surface. And I had a bit more than 40 inches of width available.

I had originally considered using a 1.25" x 13" by 36" redwood board for the table top. But as I developed the idea for the modular tab connections I decided that redwood would not make a good material for all those holes.

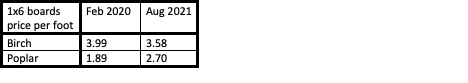

I had an 8 foot 1x6 poplar board left over from a previous project. The prices for most types of wood have increased significantly over the COVID pandemic and shutdown. But poplar and birch are still reasonably accessible. So I bought another 8 foot 1x6 piece of birch.

The tabletop was built by joining two piece of 1x6 polar using a Festool DF500 Domino machine and 6 mm Domino tenons. The boards were glued and then run through a Rikon 25-135H thickness planer to achieve a uniform finished surface. The final thickness was 17 mm.

The boards and legs were cut with a Makita XPS01 cordless tracksaw.

The joints to hold the side legs and their stretchers were done with the Domino DF500 using hardwood Domino tenons. The joints between each side leg assembly and the long stretchers and tabletop were done with the Domino DF500 and removable Festool Domino KV-SYS D8 breakdown connectors.

Domino connectors are a clever system that allows you to create IKEA-style flat-pack breakdown connectors for your joints.

The birch and poplar were finished with an oil-based polyurethane (General Finishes - Arm-R-Seal Satin). I did not feel a stain was needed although I did apply a pre-stain coat (Miniwax) before the polyurethane. The poplar boards I used had seasoned for more than a year and adopted a nice figured coloring and lost the greenish hue that poplar sometimes has when freshly cut.

The hole pattern in the tabletop is intended as a uniform connector into which modular parts can be plugged to support structures for holding specific or generic electronic modules and cables.

The holes or mortices are 6 mm x 19 mm and 10 mm deep (from the sides). They extend all the way through the 17 mm tabletop. And they are spaced 40 mm apart on centers. They can accommodate "1/4" plywood which is typically closer to 5 mm thick. They can also fit 3D printed parts. So, for example, a laser cut 5 mm plywood part with 15 mm wide and 10 mm deep tabs with 40 mm pattern spacing will easily fit into the hole pattern.

The hole pattern at the sides of the table were cut with the Festool Domino DF500. Then the holes were chamfered with a small handheld router (Makita XTR1Z).

Here's an example of a specific box I designed and built for a Pittsburgh Modular SV-1b semi-modular synth. This version of the SV-1b is in a desktop configuration called "blackbox". It's fitted into a metal case with its own power supply. (The SV-1b can also be used in a Eurorack by removing it from the blackbox case or purchasing it in the Eurorack configuration.) |

| Laser cut box to hold Pittsburgh Modular SV-1b |

|

| Accessories for table: laser cut generic supports of various sizes. Velco cable ties. 3D printed "coxcomb" for patch cables. |